Achieve precise container pressurization and reduced headspace oxygen with our Liquid Nitrogen Dosing Units. When dosed, the liquid nitrogen, at a temperature of -196°C (-320°F), rapidly evaporates due to ambient temperature, expanding from 1 liter of Liquid Nitrogen to 800 liters of Nitrogen gas. This evaporation expels air/oxygen from the container, and upon capping, builds up pressure inside, ensuring container stability and product integrity.

Our Aseptic Liquid Nitrogen Units ensure sterilized liquid nitrogen crucial for pharma-applications and Cold Aseptic Filling (CAF) processes. Despite its extremely low temperature, liquid nitrogen merely halts the growth of unwanted organisms, but doesn’t eliminate them. Our units effectively sterilize the liquid nitrogen, making it safe for sensitive applications, ensuring purity and compliance with stringent industry standards.

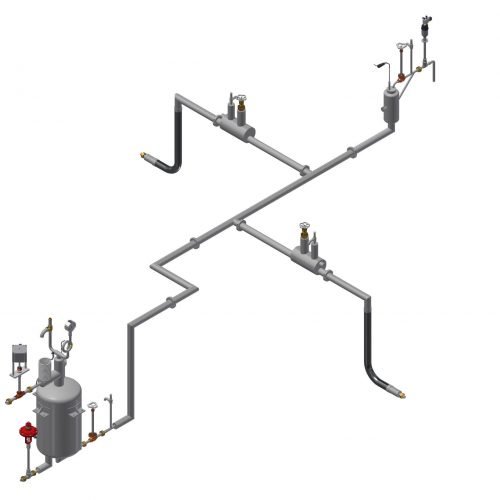

Experience utmost efficiency and safety in transporting cryogenic liquids with our VIP (Vacuum Insulated Piping), also known as vacuum jacketed piping. Expertly crafted in stainless steel, our VIP is available in both rigid and flexible configurations to suit your needs. Featuring a double-walled, welded construction, each seam is meticulously leak tested using a Helium-mass spectrometer, then pickled and passivated for enhanced durability. Our pre-manufactured sections are evacuated to end-vacuum on-site before delivery, equipped with a compensator to adjust for expansion differences between the inner and outer pipe, and a pumping outport for ease of operation.

Our skid-mounted On-Site Sterile LIN Production Units are compact, fully integrated systems designed for effortless placement on cap preparation platforms or beside the filler. Equipped with essential valves, sterile filters (0.2 μm hydrophobic) for gaseous nitrogen, steam supply for sterilization and heating, along with electrical and pneumatic cabinets, these units are ready for immediate operation. The make unit houses a process where sterile filtered gaseous nitrogen is liquefied post-system sterilization. The liquefied sterile LIN is then channeled to the S-LIN dosing head, furnished with an integrated control dosing valve. This valve, responsive to filler signals (bottle, speed, dosing position), ensures precise dosing of S-LIN into the containers, adhering to the highest standards of accuracy and hygiene.

At Terboven Cryo, we excel in customizing our offerings to meet your specific needs. If our standard products don’t align with your requirements, we’re here to collaborate and create your individualized solution.

We are Terboven Cryo, a company specializing in cryogenic application technology, with 10+ years of experience!

Copyright © 2023 Terboven Cyro | Website by Creatif.work